Field measurement is a critical and often overlooked component of railing fabrication. Recently we were lucky to chat with one of our most used miscellaneous metal fabricators, AOC Glass and Ornamental Metals. Field measurement is used during a project to confirm that rail length, angles, and other parts in the rail process are correct prior to having the metal fabricator move forward making the rails. See below for common questions regarding field measuring and how you can know when field measuring is required for a project!

What is the purpose of field measuring?

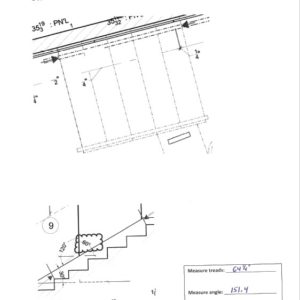

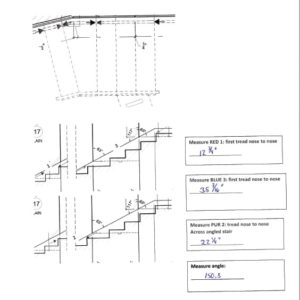

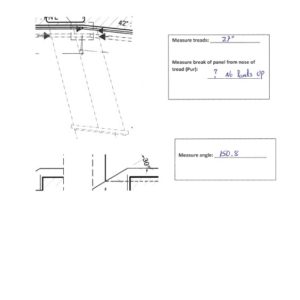

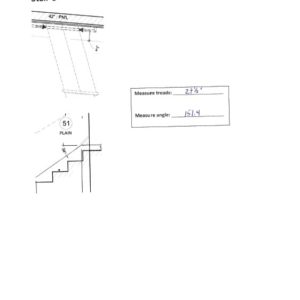

The primary objective of field measuring is to measure and establish an “as-built” substrate, i.e rampway or stair.

What are some of the key terms used in field measuring?

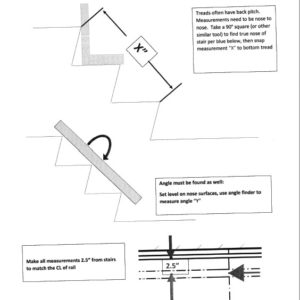

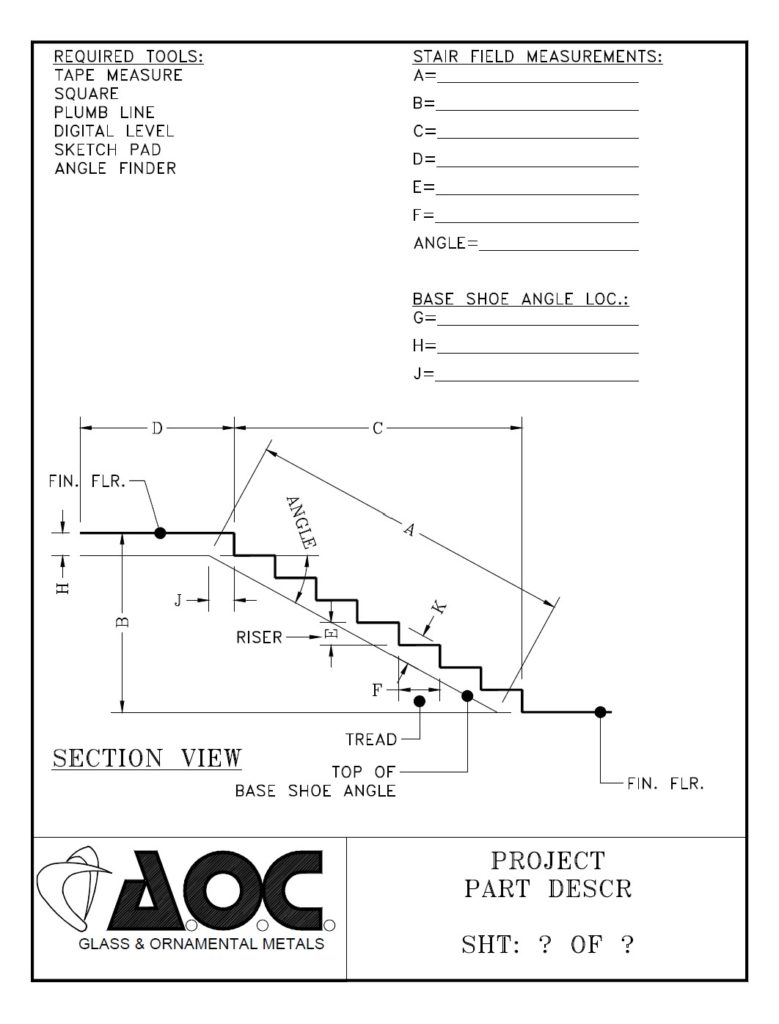

Slope – Measured in Degrees usually with a Digital level this is a sloped walking surface between two level walking surfaces. Both on a stair and on a ramp.

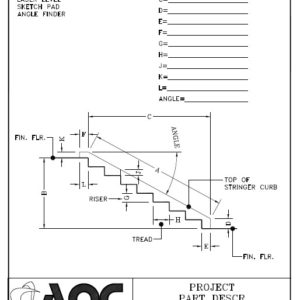

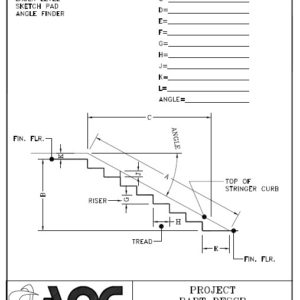

Rise – The distance a stair tread rises vertically.

Run – The distance stair tread travels horizontally.

Un-Finished Floor and Finished Floor – As field measurements are taken in various stages of the construction process, it’s important to establish if you are measuring on top of a finished flooring product, or if you will need to adjust for a floor finish when drafting because measurements were taken from an unfinished substrate.

Degree – The angle at which a slope is measured.

Elevation Offset – The delta in measured height between two horizontal walking surfaces. This measurement is used in conjunction with projected slope in lieu of, or as a double check to a slope measurement.

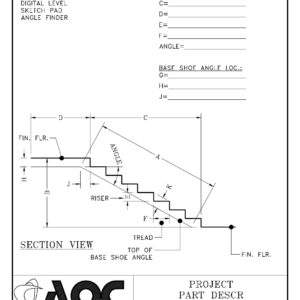

Projected Slope – On a stair a projected slope is an imaginary line that begins at the uppermost tread nose in a continuous set of stairs and travels down along all the tread noses until is touched the floor beneath the lowest most tread nose. The distance between these two points in a projected slope distance.

What is the process used for field measuring?

The process for field measuring is to identify the interacting elements and finished of a building, measure them with detail sufficient to allow their re-creation with a draftsman. This enables you to fabricate a very large portion of railings and guardrails within a controlled environment, on a fab table with clamps and flat surfaces not usually available in the field.

How does someone read the results of field measuring?

Typically the results of a detailed field measure and read as mark-ups to a detailed set of previously dimensioned shop drawings. This allows the person measuring to just strike through and re-write an accurate field measurement.

How does railing design change based on what is seen in field (i.e. does the field measurement make a railing get larger or smaller?)

Field measurement nearly always changes the size of a railing. Every trade works within a tolerance. As those tolerances grow or shrink though the construction process, a building will always deviate marginally from what the architectural dimensions call for. The point of a field measure is to make a site visit, identify these variances, and address them within your fabrication so that when you arrive to install, your product requires little to no further fabrication and it fits perfectly.

Does field measurement ever mean “starting over” with a design? Or can you generally make things work?

Generally speaking we can always make things work. There are times that you need to re-visit an anchoring detail or make minor adjustments to the overall look.

For KLIK Projects:

When will I know if field measurement is needed for my project with KLIK USA?

If you have contracted KLIK for railing fabrication, there will need to be a field visit budgeted and scheduled. KLIK can provide the field measurement, or it can be contracted locally. KLIK will fabricate to the provided field measurements so care must be taken to ensure accuracy.

Can we simply approve architectural detail in lieu of field measurements?

It is extremely rare that as-builts match the architecturals, especially in regard to pouring of concrete or fabrication of other mounting features into which railing often interfaces. If the schedule demands concurrent manufacture, you will need to budget 25-40% of overall project cost for field rework

How will field measurements impact the lead time for KLIK product?

Scheduling the site visit will add 2-3 weeks lead time if not previously scheduled. Field measurements are generally completed within a few workdays. Shop drawings are generally produced within a few weeks following this.